SOIL STABILISATION

CONSOLIDATION OF RIGID INDUSTRIAL FLOORS

SOIL STABILISATION is the quick and minimally invasive GEOSEC® solution for consolidating industrial floors, ideal for carrying out work to improve or maintain the load-bearing capacity of floor substrates. This method makes it possible to intervene quickly and economically, without having to move or dismantle heavy equipment, machinery or silos which means there is no need to interrupt your company’s usual work activities.

With SOIL STABILISATION it is no longer necessary to set up invasive, long and complex worksites; there is no need for excavation or demolition work and everything is performed cleanly, with extreme precision and swiftness, sometimes in just a few hours, thus minimizing costs and inconvenience. Furthermore, subsided industrial floors can be lifted and completely re-levelled whenever possible.

Operating procedures

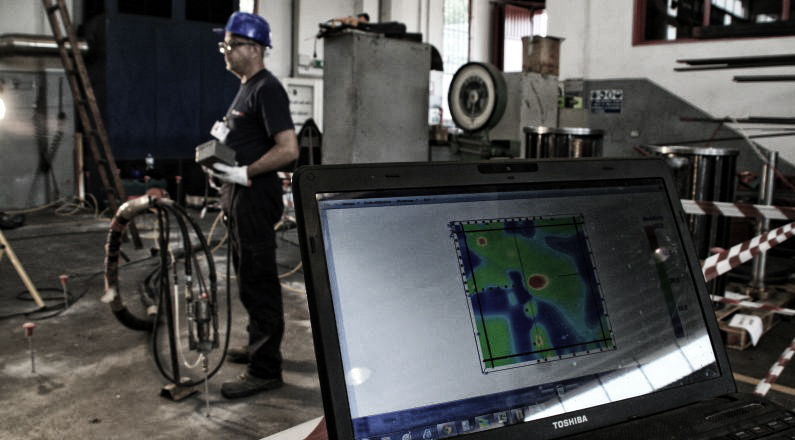

The procedure involves the injection of GEOSEC® expanding resin into the ground-structure interface of the subsided floor. During operations, instrumental monitoring of lifting is guaranteed by a laser level placed in a stable area, which detects millimetric movements thanks to a receiver positioned near the injection points. Consolidation is performed by first drilling small bores (diameter between 6 and 12 mm) in order to insert metal tubes through the subsided floor, which are then used for injecting the expanding resin.

The initial layout of the bores in the floor is generally 1.00 x 1.00 m, when the client has presented no specific requests or needs, and takes into account the conditions of the site and its operational possibilities (obstacles, the presence of any machinery and underground and/or hidden utilities, thickness of the industrial floor, the client’s production needs, etc.). The injections can also be performed near particular support surfaces for machinery and equipment both to reinforce the support base and to mitigate operational vibrations.

The GEOSEC® resin used for this procedure is a very fast expanding polyurethane resin that can be adapted according to project objectives. Should it be necessary to extend consolidation deeper into the ground, especially in the presence of very high operating loads, it is possible to adopt our patented SEE&SHOOT® method as described in the section dedicated to expanding resin injections.

Video

SOIL STABILISATION operational procedure

This procedure, used to consolidate industrial floors, involves the following work phases:

Survey phase

- Identification of areas which have not subsided;

- Positioning of the laser level in an area not affected by subsidence;

- Positioning of a levelling rod in the subsided area and measurement of the subsidence.

Preparation phase

- Drilling of an array of injection bores in the subsided floor.

Injection phase

- The required amount of expanding resin is injected into each bore;

- At the same time, when allowed for by the characteristics of the floor structure, the depressed areas are lifted to completely re-level the floor.

Technical benefits

This procedure for consolidating industrial floors provides the following benefits:

- Structural renovation of the old floor is not necessary, unless it is seriously compromised.

- Resin is injected through small-diameter bores which means the work can be performed without having to move heavy equipment or machinery out of the way.

- The whole procedure is very quick. Our teams are able to consolidate up to 80 square meters of industrial floor in a single work shift.

- The injection resin used is polyurethane-based, remains perfectly stable after reaction and is very long-lasting.

- When allowed for by the subsided structure, it is possible to lift and completely re-level subsided industrial floors and paving slabs.

- The method involves targeted resin injections also near the joints? in industrial paving slabs to remove bumps and height differences of up to several centimetres.